Leading High Performance Teams From “Concept to Commercialization“

75 Implant & Surgical Instrument Product Lines

* Plus Involvement with an Additional 15 Projects in Various Stages of Development

12

CERVICAL FUSION

Anterior Cervical Plate Systems

Mid-line Cervical Plate Systems

Combo Trial/Drill Guide Systems

Posterior CervicoThoracic Systems

Rod to Rod Cross Connectors

Head to Head Cross Connectors

Occipital Plate Systems

24

INTERBODY FUSION

Cervical Spacer Systems

PLIF Spacer Systems

tPLIF Spacer Systems

TLIF Spacer Systems

ALIF Spacer Systems

Stand-Alone Cervical Spacer Systems

Stand-Alone ALIF Spacer Systems

Cervical Allograft Spacer Systems

Lumbar Allograft Spacer Systems

Disc Space Prep Systems

15

THORACO-LUMBAR FUSION

Pedicle Screw Systems

Revision Pedicle Screw Systems

Extended Tab Pedicle Screws

Fenestrated Pedicle Screws

Expandable Pedicle Screws

Pedicle Salvage System

Cross Connector Systems

Pedicle Access Systems

Thoraco-Lumbar Plate Systems

5

CORPECTOMY

Static VBR Cage Systems

Expandable VBR Cage Systems

Modular VBR Cage Systems

Spinal Fracture Repair Systems

11

MINIMALLY INVASIVE

Cannulated Pedicle Screw Systems

Percutaneous Tower Systems

Extended Tab MIS Screw Systems

Trans-Facet Screw Systems

Trans-Lamina Screw Systems

Cortical Trajectory Screw Systems

Navigational Adaptor Systems

Unilateral Facet Screw Systems

4

INTERSPINOUS FUSION

Static ISP Devices

Expandable ISP Devices

Percutaneous ISP Devices

15

DEFORMITY CORRECTION

Titanium & Stainless Steel Systems

3.5 to 5.5mm Transition Systems

Uniplanar Pedicle Screw Systems

Monoaxial Pedicle Screw Systems

Ti, Ti Alloy, HSS, UHSS, CoCr Rods

Spinal Hook Systems

Pelvic Fixation Systems

Derotation Towers Systems

Segmental Rod Reduction Systems

4

RETRACTORS

MIS Retractor Systems

MIS Portal Access Systems

Lateral Access Systems

“Bob seamlessly merges his medical training and clinical background with in-depth industry experience to lead high performance teams that deliver innovative products to increase procedural efficiency and improve patient outcomes.”

2,125+

# of Spine Fusion

Procedures Attended

Since 2006

![]()

200+

Product Development

Surgeon Consultants

Contracted

![]()

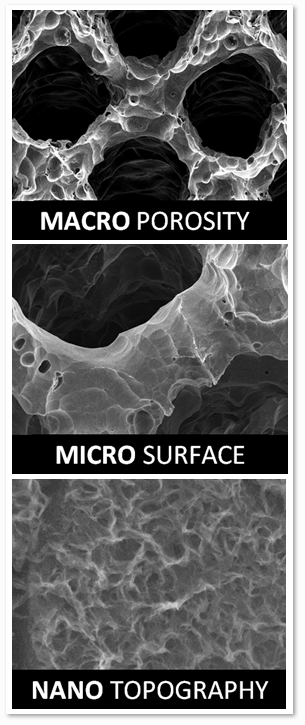

Spearheading Breakthrough Research to Improve Clinical Outcomes

NanoSmart Devices

Additive Manufacturing meets Nanotechnology

This is Smart…

Additive manufacturing utilizes high-definition 3-D laser printing to create three dimensional titanium implant scaffold designs that replicate the complex interconnected porous architecture of bone.

This is NanoSmart…

Proprietary post-manufacturing processes introduce nanotechnology to micro-roughned implant surfaces providing an optimal bioactive surface for proteins, hormones, growth factors, and stem cells to promote new bone growth and blood vessel formation through highly porous implant walls for sustainable integration of the implant within the surrounding host bone or vertebral bodies.

Exclusive Interview:

Developing Spinal Implants that Participate in the Healing Process

Dr. Robert L. Wertz, Vice President of New Product Development, sits down with Orthopedic Design & Technology to discuss development of a bioactive, 3-D printed, porous titanium implant material that stimulates bone growth and could revolutionize the spinal fusion industry. Read more…